In the downstream application industry of molds, the automotive manufacturing industry uses a large amount of molds. 95% of the parts in automotive production need to be formed by molds, and the main types of molds used include injection molds, stamping molds, forging molds, casting molds, etc. Molds are consumables with large usage. More than 90% of parts in the automotive industry are formed by molds, and cold work, hot work, and plastic mold steel are also used. By improving the injection molding process, including adjusting mold design, optimizing injection speed and temperature settings, production efficiency and product quality have been enhanced.

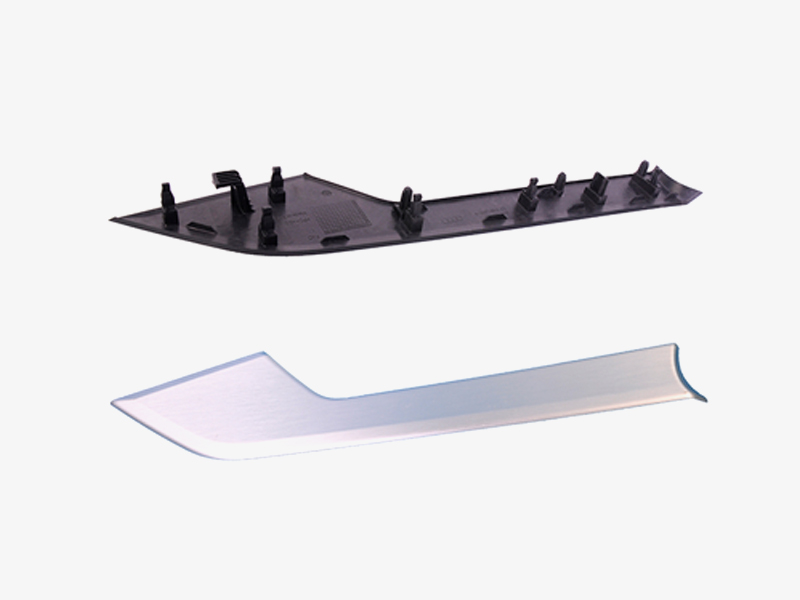

Chiweiteng specializes in the production of plastic parts for automotive interior and exterior, and has purchased dozens of injection molding machines ranging from 2500 tons, 2200 tons, 2000 tons, 1000 tons, etc., which can achieve a one-stop process of mold design, processing, trial molding, and injection molding production. Solved the problem of customer mold manufacturing and injection molding production not being done by the same company, resulting in mutual responsibility shifting due to quality issues.